PIPING WORKS

Piping works play a crucial role in the naval industry, ensuring the safe and efficient transport of fluids and gases onboard ships. However, installing piping systems can be a complex and time-consuming process, requiring skilled professionals and advanced equipment.

PIPE INTEGRATION

Hidramar International relies on the expertise and name of the Hidramar Group which is positioned in the Mid-Atlantic as a reference in the shipyards industry.

The Group was born 3 decades ago as a hydraulic and mechanical support company, given our oil and gas specialized shipyards background, we hold in-house capabilities to provide hydraulic, mechanical for pipe integration services during transit to deliver fully integrated projects on turnkey bases.

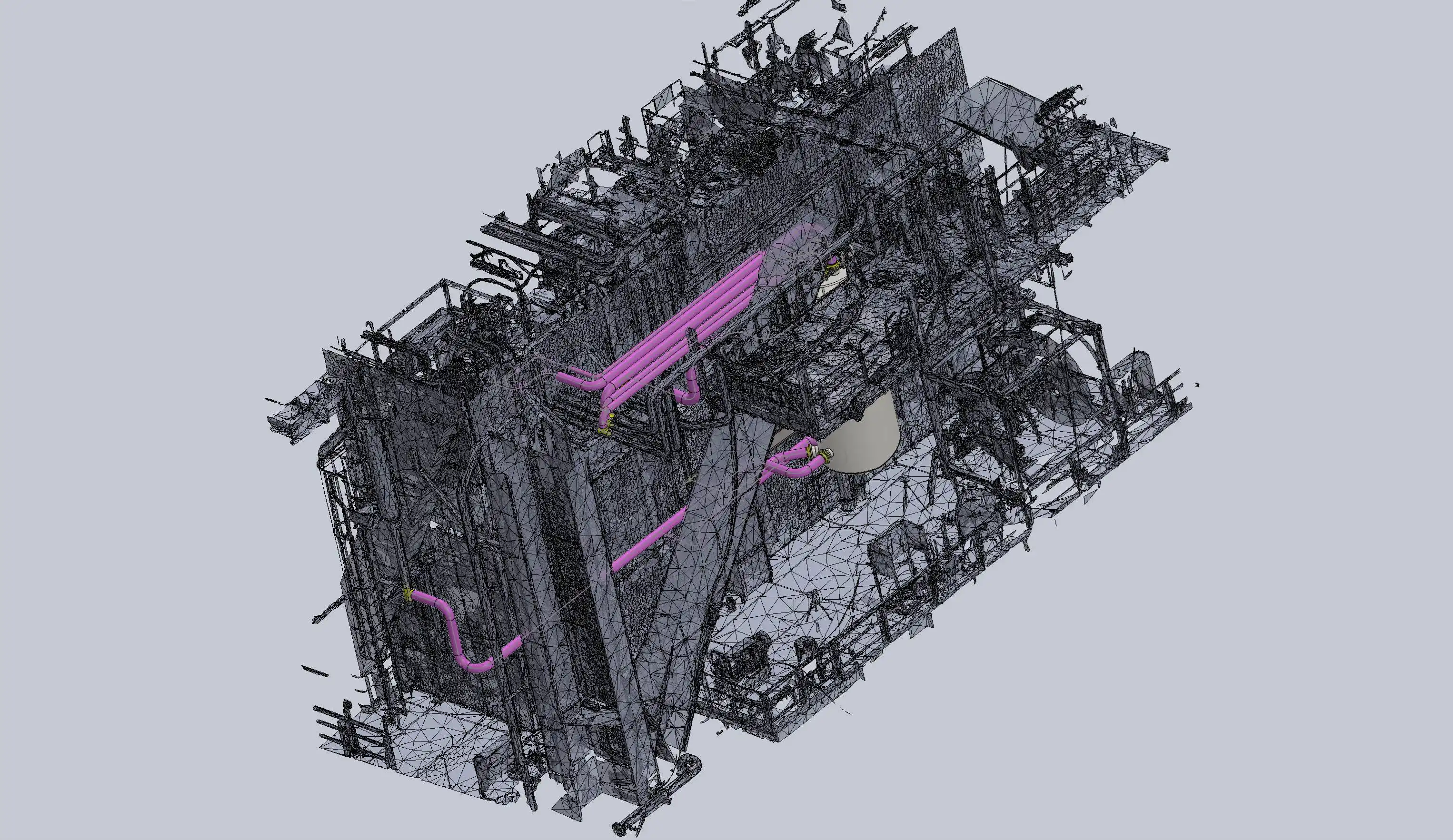

ENGINEERING FOR PIPING PROJECTS

With in-house engineering resources, our riding crew can easily provide 3D scanning services at any worldwide location offering customized solutions to our clients, not just custom-built, but also optimizing the piping work process to safely cover our customer needs within a cost-effective fabrication process, from 3D Scanning through fabrication until commissionign.

HIDRAMAR SHIPYARDS: PREFABRICATION CAPABILITIES AT OUR WORKSHOPS FOR QUALITY AND PRECISION

PRESSURE TEST CAPABILITIES

To carry out factory acceptance tests especially the pressure testing in safe conditions, a dedicated pit has been implemented with a test bench enabling pressure testing up to 2 500 bars / 36 000 PSI.

METAL ALLOYS CAPABILITIES

At our shipyards, we have special alloy workshops that give us the capabilities to fabricate different materials such as high-alloy steel grades, stainless, carbon steel, inox duplex and super duplex steel.

MATERIAL ALLOYS AND WELDING PROCEDURES

| WPS | ALLOY | PROCESS |

| T1 WPS IT 75-12 | API 5L Gr. B / X42 | ‘TIG + SMAW |

| T14 HWPS-018-001 | ASTM 106 Gr C / X52 | ‘TIG + SMAW |

| T6 WPAR HI-12-01 (316L) | ASTM A312 TP316L | ‘TIG + SMAW |

| T7 PAR HI-12-02 (904L) | ASTM B-677-97(904L) //1,4539 | ‘TIG + SMAW |

| T9 WPQR 316L 2,87 mm | SA-312 TP-316L | TIG |

| T12 WPQR 141 FW 316L to DH36 | 316L y DH36 | TIG |

| T8 WPQR HIDRAMAR 1-GTAW ORBITAL | 1.4037 | ‘GTAW |

| T3 API 5L X52 SMAW+FCAW – HWPQR-019-001-2G-BRANCH | API 5L X52 (N) | ‘SMAW + FCAW |

| T5 API 5L X52 SMAW+FCAW – HWPQR-019-001-6G | API 5L X52 (N) | ‘SMAW + FCAW |

| T11 HWPQR-013-001 | CW352H CuNi10Fe1Mn | TIG |

| T2 CunI10Fe1,6Mn HWPQR-017-001 | WL 2.1972 CuNi10Fe1,6Mn | TIG |

| T10 AISI 4130 HWPQR-015-002 | AISI 4130 | TIG |

| HWPS-HB-002 | CARBON STEEL | HARDBANDING |

| T4 API 5L X52 SMAW+FCAW – HWPQR-019-001-5G-BRANCH | API 5L X52 (N) | ‘SMAW + FCAW |

We also offer our clients technical assistance from our International Welding Engineercont (IWE) throughout the duration of their projects.

We can help you with a tailor-made solution, let’s make it happen.

From engineering to integration and commissioning